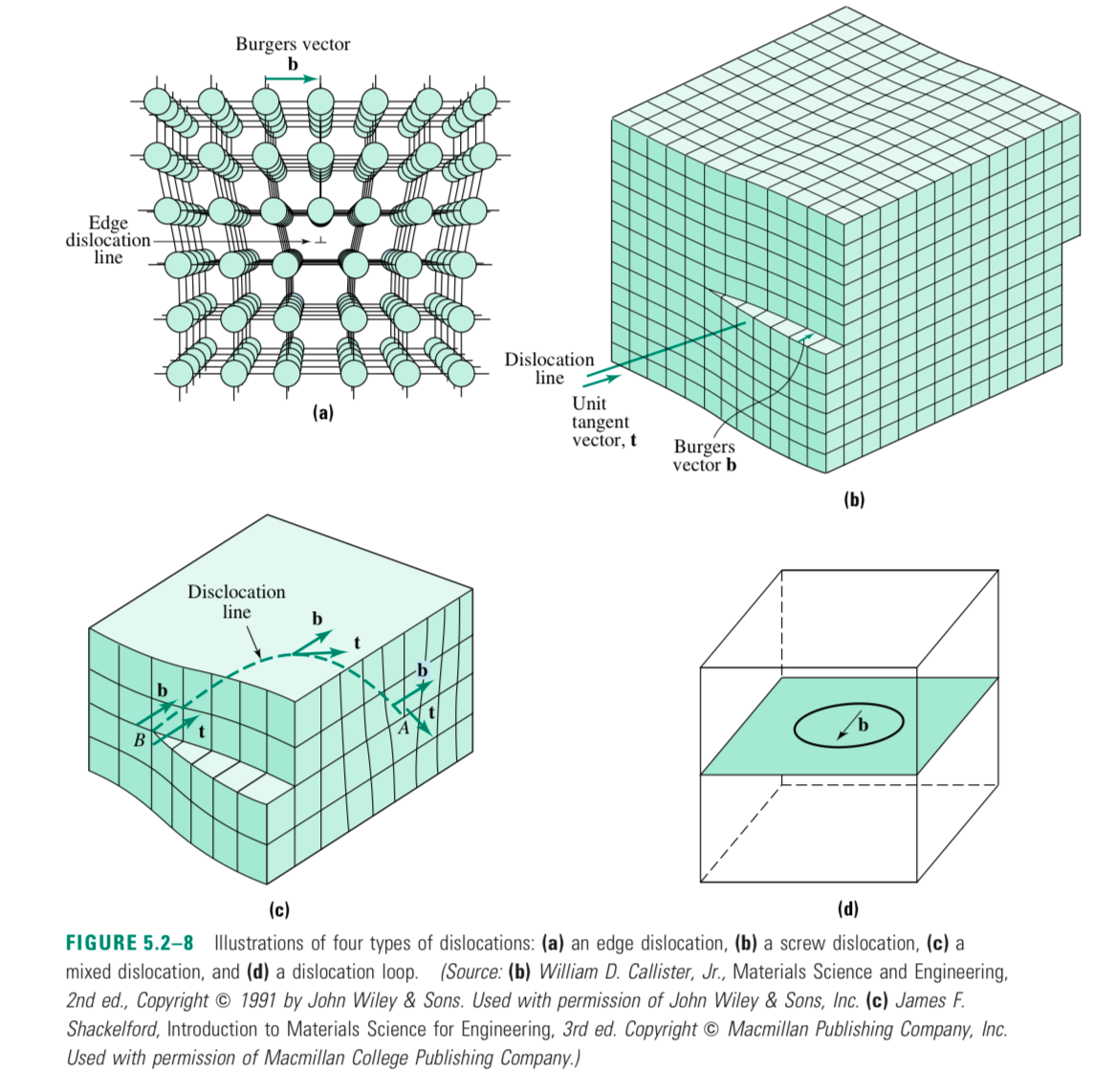

Dislocation (1D defects)

Dislocation basics

Burgers vector, tangent vector, and slip plane

- Burgers vector

- The same dislocation shares the same

- Unit tangent vector

- Slip plane

Edge dislocation

- Edge dislocation

- Edge dislocation symbol

- Vertical line: half plane, broken bonds

- Horizontal line: slip plane

Screw dislocation

- Screw dislocation

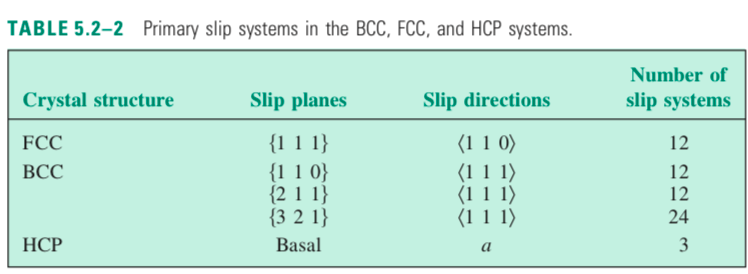

Slip system

Usually, the slip system corresponds to the highest-density plane.

Force on dislocation: Peach-Koehler force

The Peach-Koehler formula gives us the force on a dislocation line under a stress field :

Properties

The shear stress need to have a component in the direction; then consider the plane, assume pure shear, then is perpendicular to because, assume pure shear with a magnitude of , we have $$ \sigma_{ij} \, b_j = \begin{bmatrix} 0 & \tau \ \tau & 0 \ \end{bmatrix} \begin{bmatrix} b_x \ b_y \ \end{bmatrix} = \begin{bmatrix} \tau\,b_y \ \tau\,b_x \ \end{bmatrix} $$

Here, the Burgers vector is and the direction of the dislocation is given by a unit vector .

This force controls the movement of the dislocation (line). Because of the dot product, the force/movement will always be perpendicular to the dislocation line.

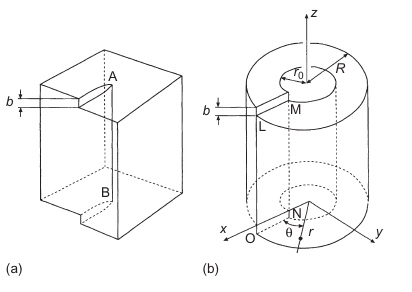

Strain, stress, and self-energy of dislocation

With the Peach-Koehler formula, we are able to obtain the force on a dislocation line under a stress field. If we have the stress field of another dislocation, we can calculate the force “between” the two dislocations.

Strain field, stress field of a dislocation

Here, denotes the shear modulus of the system and denotes the Poisson ratio.

Results

| Screw dislocation | Edge dislocation | |

|---|---|---|

| Strain | ||

| Stress | ||

| Self energy |

Important points:

- Stiffer materials have higher dislocation energy, .

- Comparatively, edge dislocation will have higher energy because of the term.

- Strain falls off as .

See also

- Point defects (0D defects), which has more of a thermodynamic aspect.

- Science and Design of Engineering Materials has a really good chapter on this topic.

- Lecture 9 - Forces on Dislocations.pdf (imechanica.org)

- Lubarda, Vlado A. “Dislocation Burgers Vector and the Peach–Koehler Force: A Review.” Journal of Materials Research and Technology, vol. 8, no. 1, Jan. 2019, pp. 1550–65. ScienceDirect, https://doi.org/10.1016/j.jmrt.2018.08.014.

- Peach, M., and J. S. Koehler. “The Forces Exerted on Dislocations and the Stress Fields Produced by Them.” Physical Review, vol. 80, no. 3, Nov. 1950, pp. 436–39. APS, https://doi.org/10.1103/PhysRev.80.436.